250-350kg/h rotating roller pellet machinery

You will find two types of flat die pellet machinery or you can say small pellet mill. They're pellet machinery with rotating die and rotating rollers. With one of these two small pellet mills, you will be aware steps to make wood pellets.

The rotating die type includes a stationary curler shaft having a rotating die, consequently when making wood pellets the die is rotating as the rollers are stationary. While the working principle of rotating roller type pellet machinery is totally different from the prior one, which features a stationary die having a rotating curler shaft, then when working the die is stationary however the rollers are rotating.

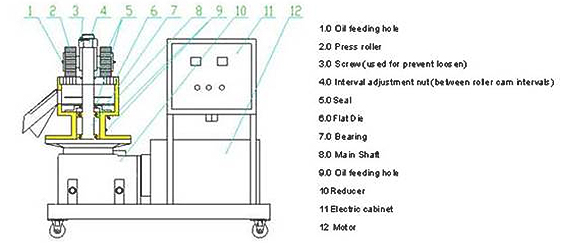

Structure and main parts of the rotating roller type ZLSP-R pellet machinery

Model ZLSP R-Type series rotating roller pellet machinery is specialized in industrial biomass fuel field, which is most suitable to process sawdust, straw, bamboo crumbs, peanut shell, bagasse, alfalfa and so on.

|

Model | ZLSP300A |

|---|---|---|

| Power | 36HP | |

| Capacity | 250-350kg/h | |

| 550-770lbs/h | ||

| Weight(NW/GW) | 850/890kg | |

| 1874/1962lbs | ||

| Packing Size | 1100*700*2480mm | |

| 43*28*98 inch | ||

|

||

|

Model | ZLSP300B |

|---|---|---|

| Power | 22KW | |

| Capacity | 250-350kg/h | |

| 550-770lbs/h | ||

| Weight(NW/GW) | 540/575kg | |

| 1190/1268lbs | ||

| Packing Size | 1350*750*1400mm | |

| 53*30*55in | ||

|

||

|

Model | ZLSP300C |

|---|---|---|

| Power | 22KW | |

| Capacity | 250-450kg/h | |

| 550-882lbs | ||

| Weight(NW/GW) | 550/585kg | |

| 1213/1290lbs | ||

| Packing Size | 1450*850*1400mm | |

| 57*34*55in | ||

|

||

Our spare parts are reliable for you to use. There is much superiority they can offer you:

- Pellet mill spare parts of GEMCO are manufactured standardized, so that you shouldn't worry about whether the size is appropriate or not.

- Each detail of spare parts is made under strict supervision of quality department, like the intensity and depth of die.

- The aperture on the die is changeable so that you can produce pellets with certain size as you need.

- Customization is possible. If you have some special demand, GEMCO can manufacture spare parts accurately for you.

|

|

|

| Main components are made of alloy steel, so that the durability is strengthened. | Rollers and die have uniform specification so that replacement is available. | Both sides of dies are applicable so that the usage life is prolonged. |

|---|

Regarding the benefits of pellet machinery with rotating roller design, we generally conclude into two primary aspects. On one side, the style of rotating roller has considerably longer service existence compared to traditional design, it's about 2000 hrs. On the other side however, the size of the wood pellets which created by the style of rotating roller is a lot longer too, it may be 3cm or even more.

Your privacy is safe with us. We hate spam as much as you do.

Related Equipment

Products list

Latest News

Jul 27, 2015

GEMCO is Now a Division of ABC MachineryFrom now on, GEMCO will conduct its business under the ...

Apr 11, 2015

GEMCO Will Attend 117th Canton FairThe 117th China Import and Export Fair() will be held d...

Recommend Products

small mobile pelletizing system

MPL300 small mobile pelletizing system is a compact pell...

MPL300 small mobile pelletizing system is a compact pell...

wood pellet mill

How are wood pellet made? Here is professional wood pell...

How are wood pellet made? Here is professional wood pell...

homemade pellet mill

Homemade pellet mill is now a hot sale machine for the c...

Homemade pellet mill is now a hot sale machine for the c...

electric pellet mill

The D-Type mini pellet mills are powered with an electri...

The D-Type mini pellet mills are powered with an electri...